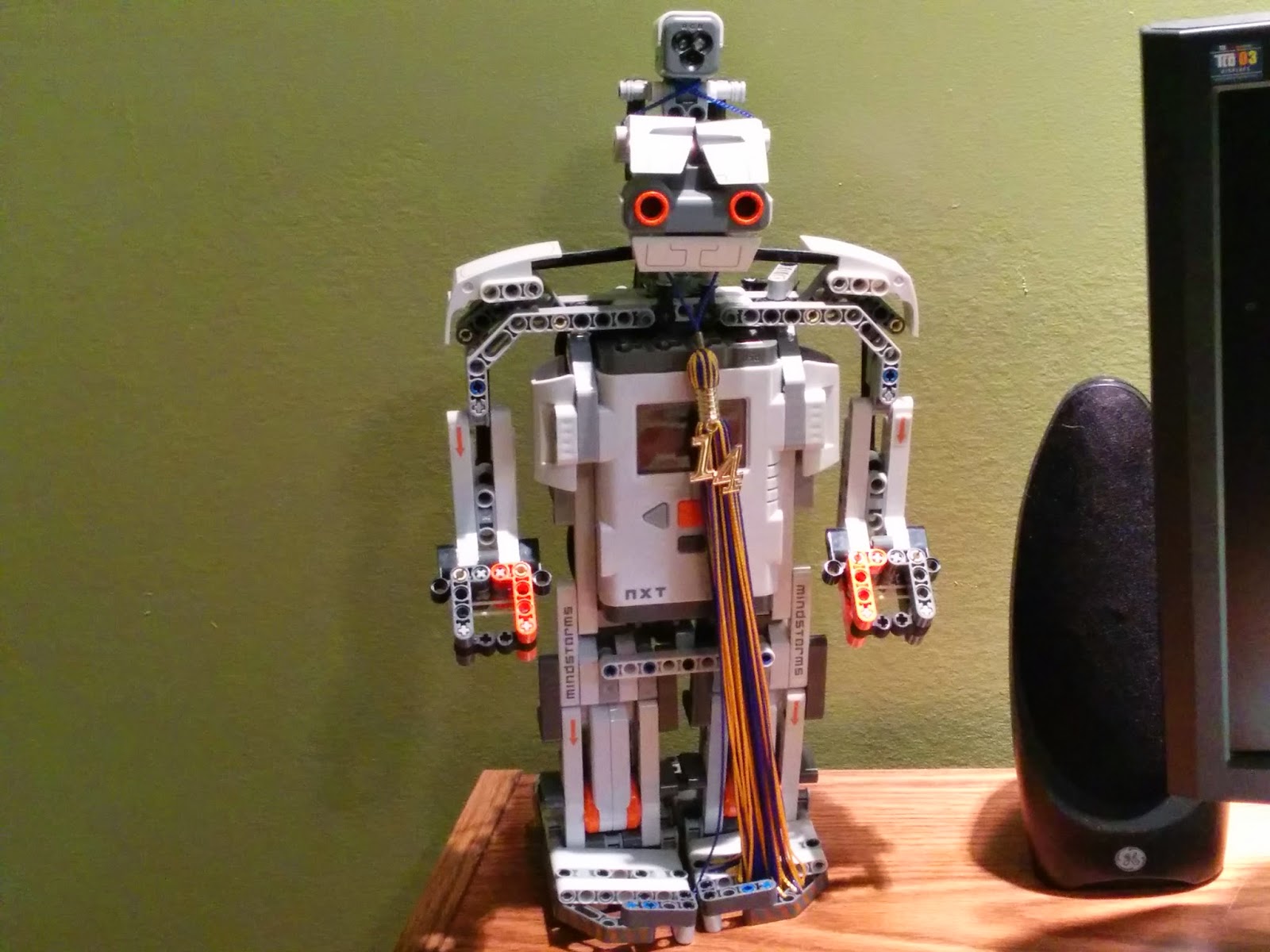

After I worked with the LEGO Mindstorms kit (see my post here), I moved onto BOE-Bot – an educational robotics kit – that teaches basic electric circuits and robot control. I picked up my kit at the Boy Scouts store (back when I was actively in Boy Scouts of America) as part of the robotics merit badge. When I built it, I found the accompanying book very helpful when learning PBASIC (the textual programming language used).

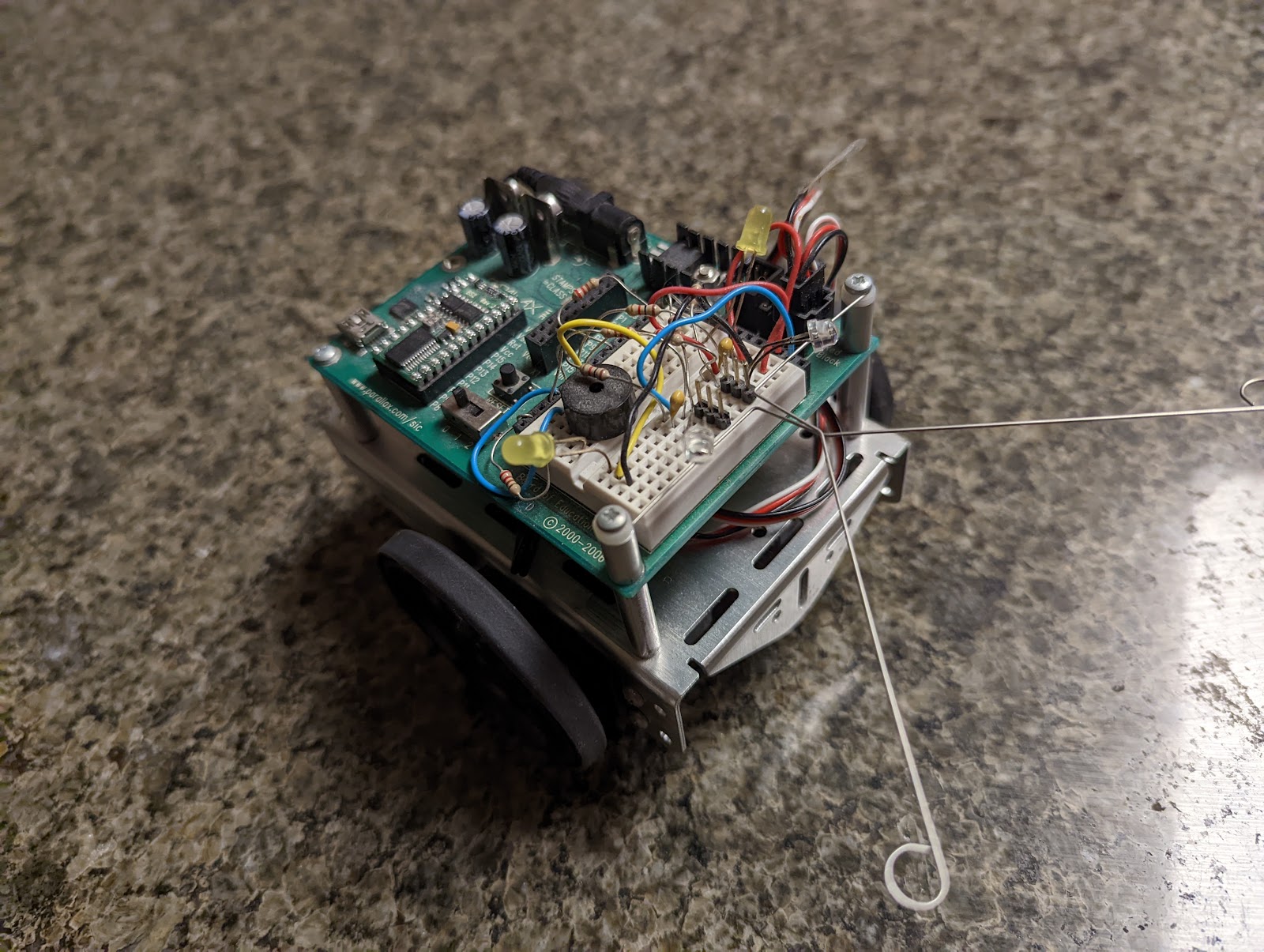

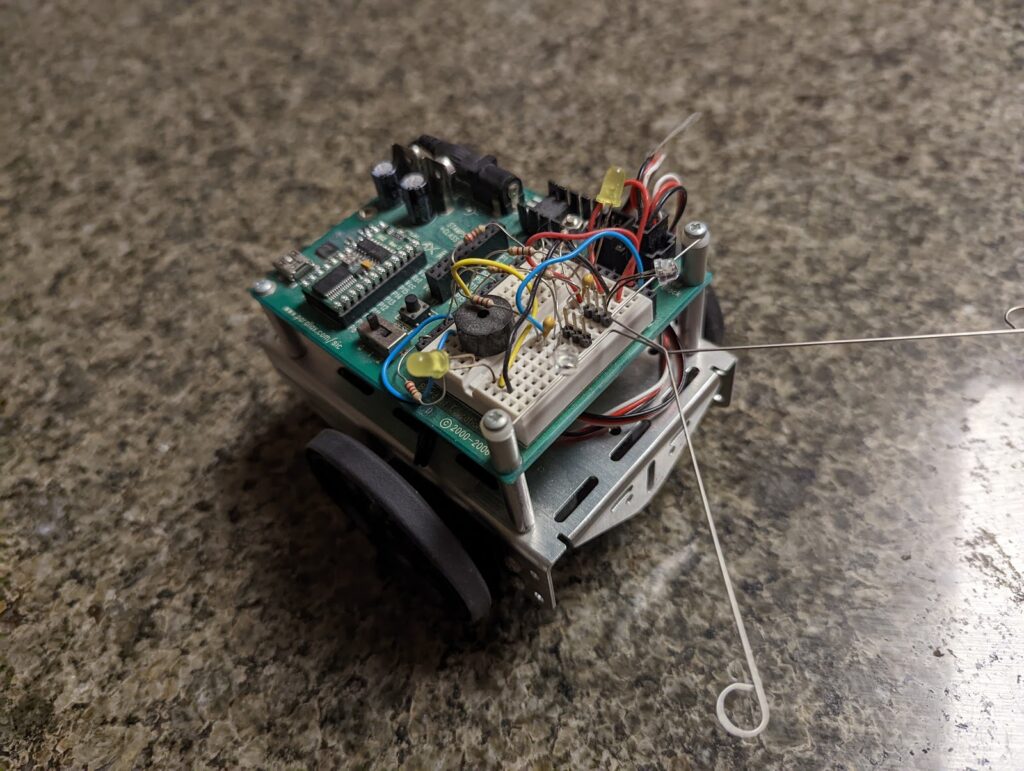

My BOE-Bot with phototransistor eyes and collision whiskers.

The core of BOE-Bot is the Basic Stamp microcontroller. Its a small DIP IC/PCB with a (old) PIC microcontroller and EEPROM that is programmed using PBASIC (Parallax BASIC). This microcontroller hooks up to the Board of Education (BOE) that provides breakout of the GPIO, power regulation, and a small breadboard for various simple circuits. It also provides a handy breakout for servo motors.

BOE-Bot with the official textbook.

The robot kit itself is well built, with a polished aluminum chassis to house two servo motors and the BOE. The wheels themselves are less great. While the plastic is sturdy (it has survived several years of use), you have to cover them with a rubber band that is tricky to get on. Plus this rubber band degrades over time. I did buy a large set from Digikey on a recent repair of this robot. This seems to be fixed in new versions of the kit but alas I did not get that version back in the day.

Onto the circuit. I followed the accompanying book, Robotics with the Boe-Bot by Andy Lindsay, to build several rudimentary circuits along with the code to interact with them. Each of these circuits teach fundamental concepts in embedded systems and I was glad that the book eased me into each one. I will detail each below.

The Circuit

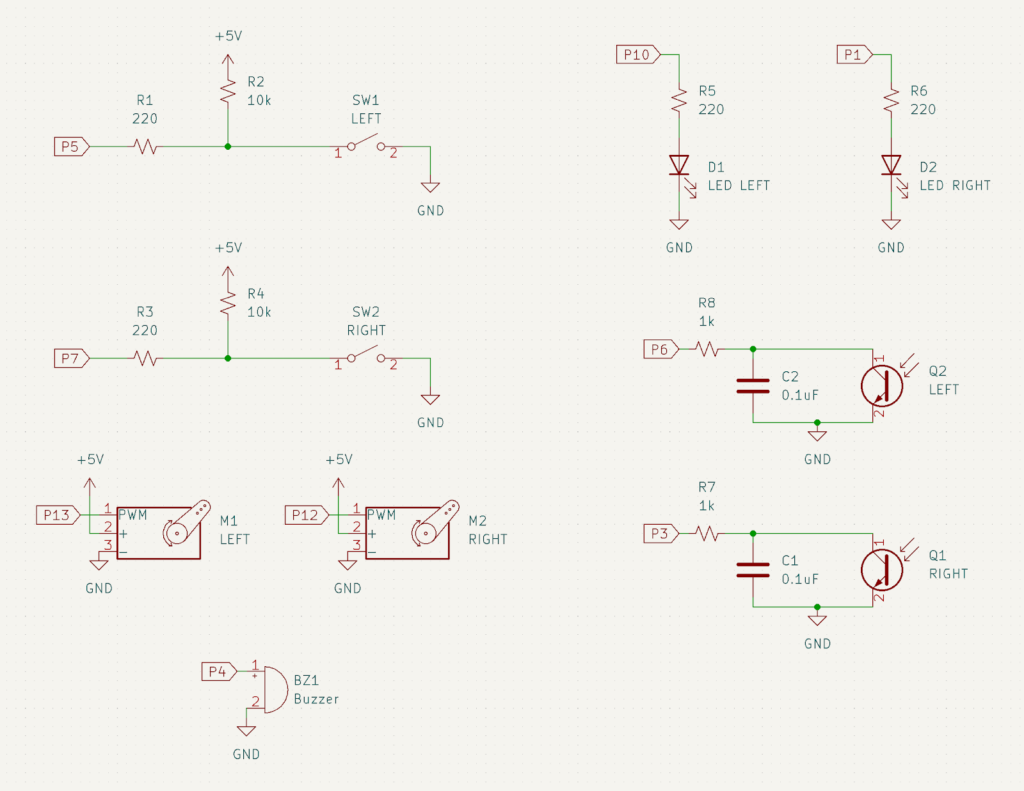

Schematic capture of the circuits built for BOE-Bot. Not shown is the microcontroller itself; pins noted (P1, P3, P4, P5, P6, P7, P10) are the pins on the board of education breakout. Servo motors are broken out in a separate connector (P12, P13).

Whisker Switches – Driving forward is all well and good until you crash into something at which point, if your robot can’t detect that it has stopped moving, it will helpless continue attempting to drive forward. These whiskers offer a simple electro-mechanical sense of collision. The collision circuits connect to digital input pins (P5 for left whisker and P7 for right whisker) to a current limiting resistor and a pullup resistor. Normally, the whisker switch is open (not in collision) so the pull up resistor connected to +5V pulls the rest of the circuit and the digital input pin up to +5V. This works because of Ohm’s law: V = IR. Assuming the digital input doesn’t draw any current then there is no voltage drop over the 10k resistor.

However, when the switch is pressed the digital input line short-circuits to ground (0V). So why doesn’t our circuit blow up? Because we properly chose a pullup capacitor with a high enough resistance such that a 5V drop across it is 0.5 mA and dissipates 2.5mW (P = VI).

What about the other resistor in series with the digital input? Well this is mostly for our protection. As a general rule, microcontrollers can only source or sink so much current. So putting this resistor in helps us if we accidentally program this pin to be an output. We would be fine if we set the output to low since it would just sink (that means pull in) current from +5V through a large resistor. But if we didn’t have the in series 220 resistor and we set the pin to be high (at +5V) then we would be in serious trouble. In this scenario our microcontroller is being asked to supply as much current as possible, which will certainty cause it to break. But with the resistor we only will source (push out) 25ish mA, high but reasonable.

LEDs – Another staple circuit is the humble LED. On BOE-Bot we are using these to indicate turning direction (explained more in the programming section). The circuit itself is a digital output pin connected to a current limiting resistor to a diode to ground. In this configuration we are sourcing current from the microcontroller (about 20 mA assuming a standard voltage drop over the diode). In this configuration we can set the pin to HIGH (one or +5V) to turn the LED on and LOW to turn the LED off.

We could have also sunk current from an LED connected to +5V but then our LED is active LOW (pin is grounded) when LED is on, which is frankly just a bit harder to think about. One would want to do this if we expected a higher current load as there is this general rule that its easier for electronics to sink current than to source it.

Continuous Rotation Servos – BOE-Bot is a mobile robot that uses two continuous rotation servos for its differential drivetrain. A servo motor is simply a motor with some kind of internal feedback / control loop. Normally a servo motor is used to move to a particular position (think motors for a robot arm). The ones on BOE are continuous meaning they are able to spin freely also we give a target speed instead of position.

Commanding a servo motor requires a digital output pin to produce a PWM (pulse width modulation) waveform. The PWM waveform has parameters of duty-cycle and frequency. Frequency tells us how quickly we cycle our digital output pin from HIGH to LOW and back to HIGH. Duty-cycle tells us how long we should stay HIGH (or LOW) within a single period of the waveform.

Back to servos, by changing the duty cycle we are telling the servo to change its speed and direction. For instance, sending a PWM wave with a duty cycle of 50% (half the time on, half the time off) will result in a speed of zero. But if we send a duty of 80% we tell the servo to move clockwise at roughly 60% speed. Or if we send a duty cycle of 10% then we are moving counter clockwise 80% speed.

Notice that our frequency doesn’t change when we adjust duty cycle. For PWM servo motors there is an acceptable range of frequencies and as long as we are within that range the motor itself will be more than happy to interpret the PWM as a speed.

* Lastly, if we were talking about positional servos all of the above would be true except instead of speed we would map angular position to duty cycle.

Phototransistors – The eyes are the windows to the soul… err world. In our case, BOE-Bot’s eyes are two phototransistors pointed left and right. The circuit used has a clever charge-and-decay trick to determine an analog (not just binary) light level. Our goal is to use this to steer BOE-Bot toward the light as a photovore.

Microcontrollers are inherently digital, binary devices. They think in ones and zeros. But our world is not just on or off, it’s every step in-between and the kitchen sink. Light itself has a degree of brightness even if your light source is either on or off. If we want our robot to see this we need some way of converting the analog value of brightness into a number (as a formatted set of ones and zeros). Fancy microcontrollers have built-in ADCs that can be directly hooked up and with a bit of programming will spit out a number. Our Basic Stamp ain’t as fancy but it can do something similar (its kind of how an ADC works under the hood) by charging up a circuit and then waiting for it to naturally drop back to zero volts.

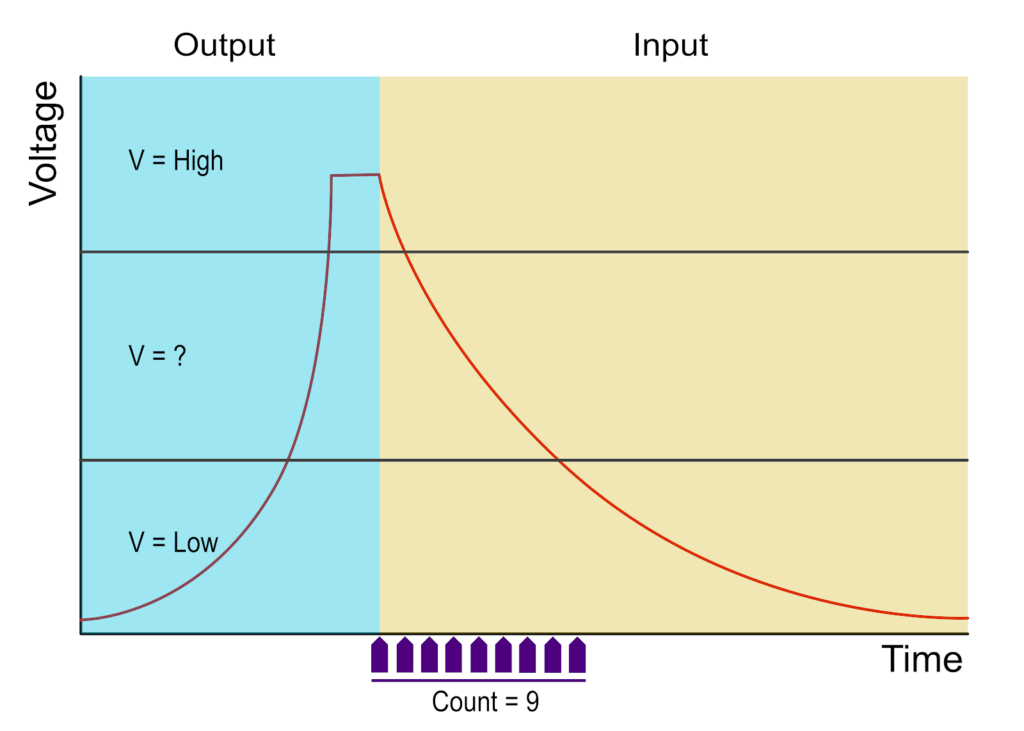

In our circuit we use a capacitor and and the transistor as a sort of light adjustable RC circuit. RC circuit just means resistor capacitor circuit. The process starts by setting our pin to output HIGH (+5V) voltage, charging up the capacitor, and then switch our pin to input. We now read back HIGH. So we wait a bit and check again; still HIGH. And again until it reads LOW. During that time we count each check we did. The more checks the longer it took to decay to LOW and thus it has a higher resistance.

Graph of RC charge-decay process. X axis is time. Y axis is Voltage. The process starts with pin outputting a high voltage to charge up the capacitor. Then pin changes to input. Capacitor voltage decays due to phototransistor leaking current. During this time, the microcontroller checks for the voltage to go back to a low state; finding nine checks were needed.

The electrical theory is a bit more complex but generally speaking the phototransistor only allows so much current to flow out of the capacitor. A phototransistor itself has a “resistance” affected by the ambient light level. In a bright, sun-filled, room the effective resistance is very low (phototransistor is ON) but in a dark room with the light off, the resistance is near infinity (phototransistor is OFF). Between those two states is some mapping of current flow to brightness.

Once we check both RC circuits in the code, we can compare the light levels on the left and right side of BOE-Bot. Then similar to an op-amp BEAM photovore we can steer toward the light.

Piezo Buzzer – A buzzer provides an audible tone, useful for indicating state of the robot. The circuit is merely a digital output connected to the piezo buzzer. When we apply a square wave at a certain range of frequencies the buzzer vibrates producing an audible sound. Similar to the servo motor we are using PWM, except now we are mapping frequency to audible tone while holding the duty cycle constant.

The Program

My code can be found on Github under Simple-Hobby-Robots/BOE-Bot. Note that the code hasn’t been maintained. And while I am going to discuss the spaghetti code here, I don’t really plan on improving it. The purpose of this post is to reflect back on the code I wrote; documenting some useful / teachable aspects.

First keep in mind the following convention for left and right of BOE-Bot.

We will refer to left and right of BOE-Bot as shown.

Let’s look at the first snippet, which handles memory allocation and initialization.

'Hardware defined constants

LIGHT_SENSE_LEFT CON 6

LIGHT_SENSE_RIGHT CON 3

BUZZER CON 4

TOUCH_SENSE_LEFT VAR IN5

TOUCH_SENSE_RIGHT VAR IN7

LED_LEFT CON 10

LED_RIGHT CON 1

MOTOR_LEFT CON 12

MOTOR_RIGHT CON 13

'Memory Allocation

pulseCount VAR Byte

cornerCounter VAR Byte

cornerCounter = 0

lightLvlLeft VAR Word

lightLvlRight VAR Word

i VAR ByteThis section of code defines constants for hardware connections, such as sensor pins and motor control pins. It also allocates memory for global variables used throughout the program.

Snippet two, main loop.

main:

'Initial startup frequency to notify that the program has indeed started

FREQOUT BUZZER, 2000, 3000

'run the robot program forever!

DO

'turn off LEDs

LOW LED_LEFT

LOW LED_RIGHT

'IF touch sensors are not pressed then follow the light

IF TOUCH_SENSE_RIGHT = 1 AND TOUCH_SENSE_LEFT = 1 THEN

'read the light values from sensors

HIGH LIGHT_SENSE_LEFT

PAUSE 1

RCTIME LIGHT_SENSE_LEFT, 1, lightLvlLeft

HIGH LIGHT_SENSE_RIGHT

PAUSE 1

RCTIME LIGHT_SENSE_RIGHT, 1, lightLvlRight

'If the light level low then ignore the light sensor behavior AND just run a

'wall banger script for a bit

IF (lightLvlLeft < 100 AND lightLvlRight < 100)THEN

GOSUB wallBangerLoop 'will kick out of loop after some time period

'If the light level too high then ignore the light sensor behavior

'AND just run a wall banger script for a bit

ELSEIF(lightLvlLeft > 20000 AND lightLvlRight > 20000) THEN

GOSUB wallBangerLoop 'will kick out of loop after some time period

'If the left has less light than right side then turn right

ELSEIF lightLvlLeft < lightLvlRight THEN

GOSUB rightPulseSoft

'If the right has less light than left side then turn left

ELSEIF lightLvlLeft > lightLvlRight THEN

GOSUB leftPulseSoft

'If they are equal value then go straight

ELSE

GOSUB forwardPulse

ENDIF

'touch sensors are pressed determine which one it is and take evasive action

ELSE

GOSUB takeEvasiveAction

ENDIF

LOOPThe main loop consists of two primary behaviors: light-seeking and obstacle avoidance. If not touch sensors are activated, the robot will follow the light-seeking routine. If a touch sensor is activated, the robot will take evasive action via “takeEvasiveAction” routine. There is also a way to short-circuit the light-seeking routine if the light sensors are producing data at the extremes (too bright or too dark of an environment) that is handled by a “wallBangerLoop” routine.

The light-seeking routine itself is pretty straightforward.

- If the left sensor is brighter than the right sensor then turn left

- If the right sensor is brighter than the left sensor then turn right

- Else keep going straight

Snippet three, obstacle avoidance behavior.

takeEvasiveAction:

'IF the touch sensors are not both active then increment

'a counter since BOE-bot may be in a corner, if enough times

'in this then BOE-bot will backup and spin 180

IF (TOUCH_SENSE_RIGHT <> TOUCH_SENSE_LEFT)THEN

cornerCounter = cornerCounter + 1

'In a corner so backup and leave corner

IF (cornerCounter > 4) THEN

cornerCounter = 0

HIGH LED_LEFT

HIGH LED_RIGHT

GOSUB backup

LOW LED_LEFT

LOW LED_RIGHT

GOSUB turnLeft

HIGH LED_LEFT

HIGH LED_RIGHT

GOSUB turnLeft

ENDIF

ENDIF

'IF both sensors pressed then turn 180 degrees

IF (TOUCH_SENSE_LEFT = 0) AND (TOUCH_SENSE_RIGHT = 0) THEN

HIGH LED_LEFT

HIGH LED_RIGHT

GOSUB backup

GOSUB turnLeft

GOSUB turnLeft

'If left sensor is pressed the turn right

ELSEIF (TOUCH_SENSE_LEFT = 0) THEN

HIGH LED_LEFT

GOSUB backup

GOSUB turnRight

'If right sensor is pressed then turn left

ELSEIF (TOUCH_SENSE_RIGHT = 0) THEN

HIGH LED_RIGHT

GOSUB backup

GOSUB turnLeft

ENDIF

RETURNThis snippet contains the “takeEvasiveAction” subroutine is designed to determine when the bot is stuck and execute appropriate maneuvers to get out of the tricky situation it finds itself in. By reading the state of its touch sensors, the robot not only reacts immediately to obstacles but also accumulates data to detect repeated collisions.

The logic is somewhat straightforward:

- Corner Detection: If one sensor is activated while the other is not, a counter increments. After a few occurrences, the bot backs up and performs a 180° turn. Presumably if we keep oscillating (and thus incrementing the counter) we are stuck in a corner or other weird situation. Retreating back to known navigable space is better than bouncing back and forth.

- Direct Obstacle Response: When both sensors are triggered, BOE-Bot immediately reverses and turns 180°. We have probably collided with a wall head-on.

- Single Sensor Response: A single sensor trigger results in a backup and a turn in the opposite direction of the activated sensor.

Additionally, we use the LED indicators to visually signal which maneuver is being executed.

Snippet four, wall banger routine

wallBangerLoop:

FOR i = 0 TO 100

IF TOUCH_SENSE_RIGHT = 1 AND TOUCH_SENSE_LEFT = 1 THEN

GOSUB forwardPulse

ELSE

GOSUB takeEvasiveAction

ENDIF

NEXT

RETURNThis snippet simply blocks within a loop for 100 cycles and either moves forward if neither touch sensor pressed or takes evasive action (as described above).

Nomenclature: Wall-banger is a common term used to describe a robot that is driving around (perhaps with a goal like mapping or could be just existing) and detects walls, rotates, drives, detects wall, etc.

Snippet five, movement subroutines.

turnLeft:

FOR pulseCount = 0 TO 20

GOSUB leftPulseHard

NEXT

RETURN

turnRight:

FOR pulseCount = 0 TO 20

GOSUB rightPulseHard

NEXT

RETURN

backup:

FOR pulseCount = 0 TO 40

GOSUB backupPulse

NEXT

RETURN

forwardPulse:

PULSOUT MOTOR_RIGHT, 850

PULSOUT MOTOR_LEFT, 650 ' used to be 850 but is set for correction

PAUSE 20

RETURN

leftPulseHard:

PULSOUT MOTOR_RIGHT, 650

PULSOUT MOTOR_LEFT, 650

PAUSE 20

RETURN

leftPulseSoft:

PULSOUT MOTOR_RIGHT, 850

PULSOUT MOTOR_LEFT, 720

PAUSE 20

RETURN

rightPulseHard:

PULSOUT MOTOR_RIGHT, 850

PULSOUT MOTOR_LEFT, 850

PAUSE 20

RETURN

rightPulseSoft:

PULSOUT MOTOR_RIGHT, 780

PULSOUT MOTOR_LEFT, 650

PAUSE 20

RETURN

backupPulse:

PULSOUT MOTOR_RIGHT, 650

PULSOUT MOTOR_LEFT, 850

PAUSE 20

RETURNThese subroutines control BOE-Bot’s low-level movements, such as turning left, right, backing up, and moving forward. Each subroutine sends appropriate control signals to hardware for a calibration duration.

Closing Thoughts

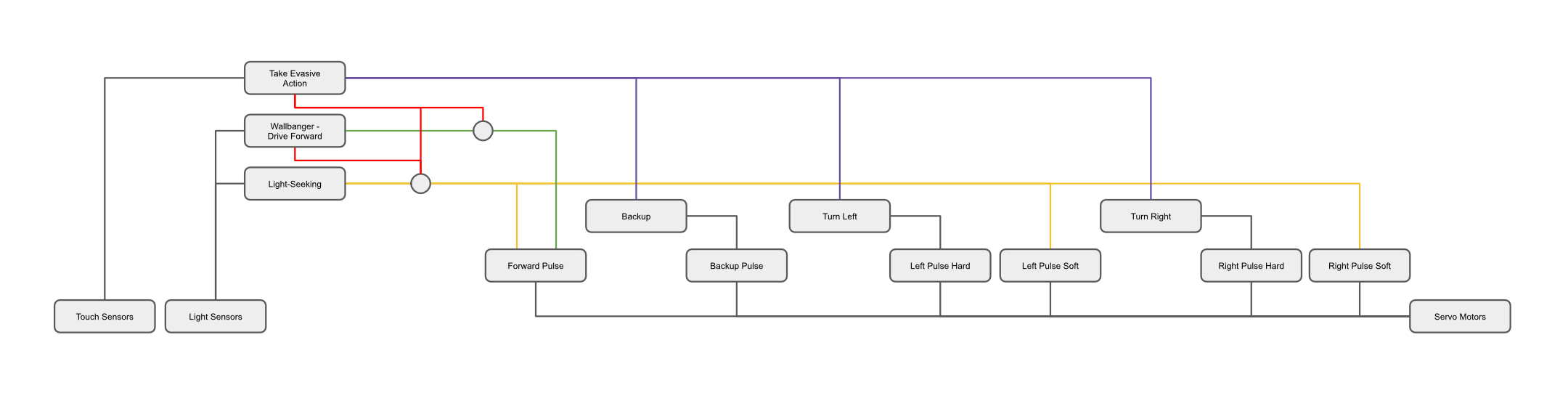

I want to wrap everything up in a neat little bow by documenting the subsumption architecture controlling BOE-Bot.

Nomenclature: Subsumption Architecture is a behavior-based approach that organizes a robot’s behavior into layers, with each layer responsible for a specific task. Higher layers can subsume (or suppress) the output of lower layers to control the overall behavior of a robot.

Below is the subsumption architecture diagram starting on the left-bottom with sensors, moving through the subsumable control layers, and on the right is lower-level motor control primitives. Notably, the snippets we discussed earlier for light-seeking behavior is subsumable by the wall banger routine if the light level is out of bounds. Both wall banger and light-seeking are subsumable by the the evasive action behavior triggered when the touch sensors detect collision.

Subsumption Architecture for BOE-Bot.

In my journey through robotics back in high school, I muddled the implementation details of programming, circuits, and mechanics with the theoretical control structures. But I think this is okay. A novice doesn’t need to grasp the architecture when they are first tinkering. Doing is better than not.

But it is also good to reflect on what was built and what could have been improved (even if the improvement will never actually be implemented). Generating and understanding the architecture diagram (even if its after the fact) is probably the most impactful part of this exercise.

Feel free to comment and provide feedback. Keep building.